da fabritrento » 30/10/2013, 7:54

da fabritrento » 30/10/2013, 7:54

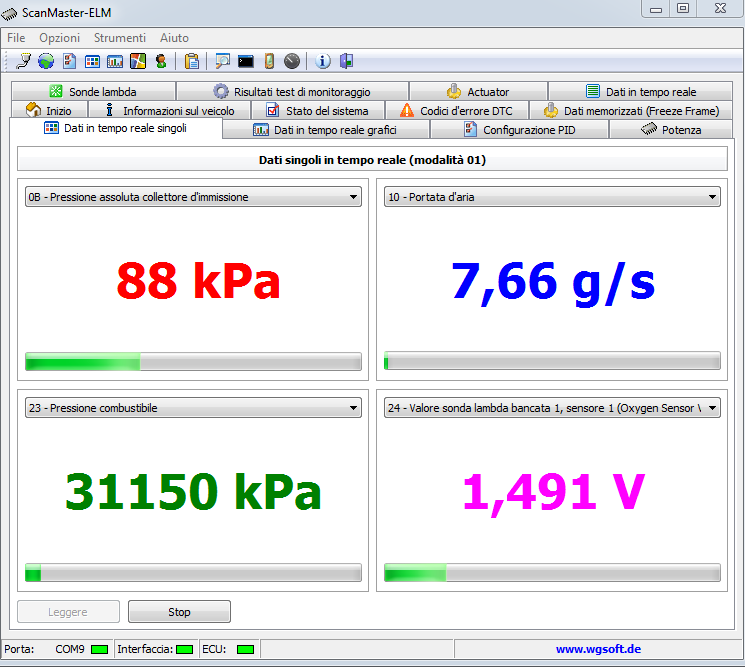

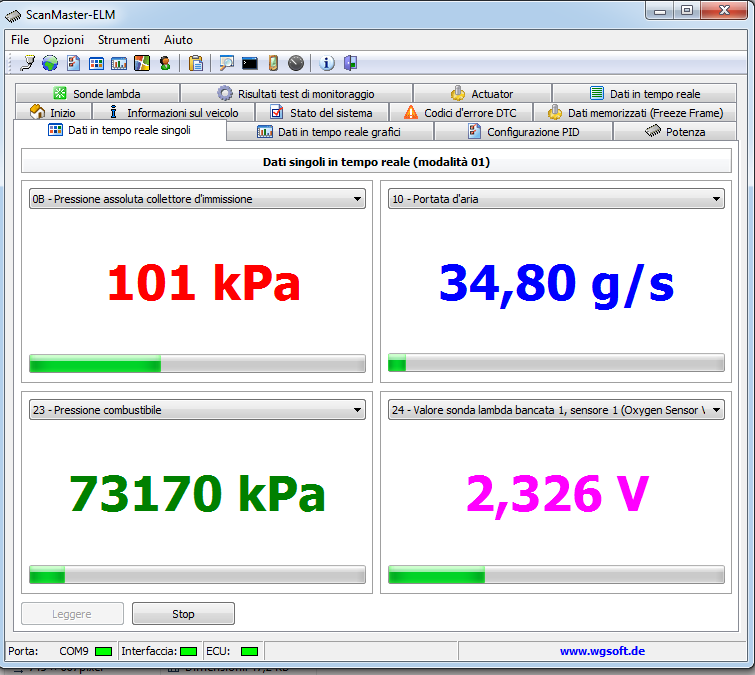

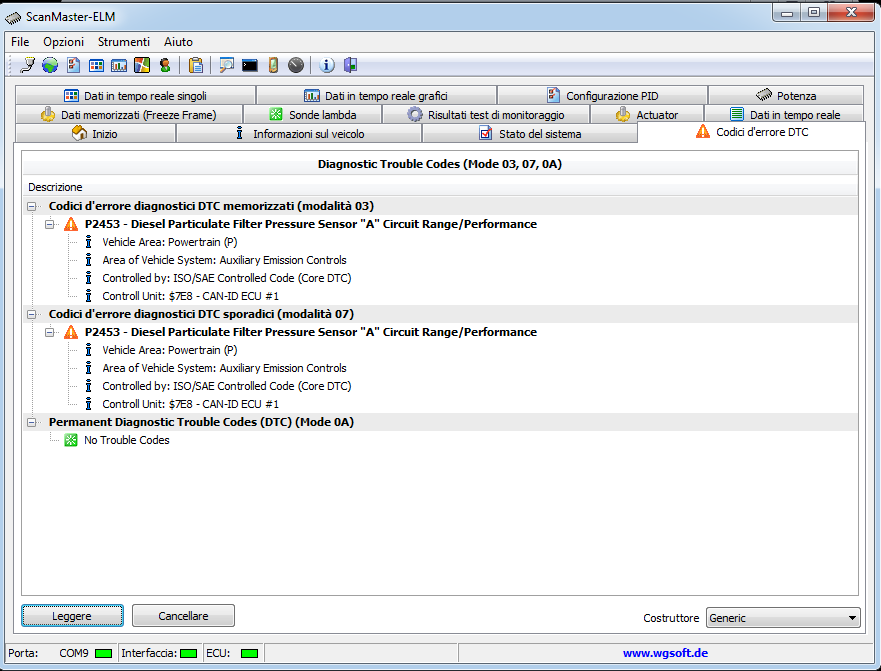

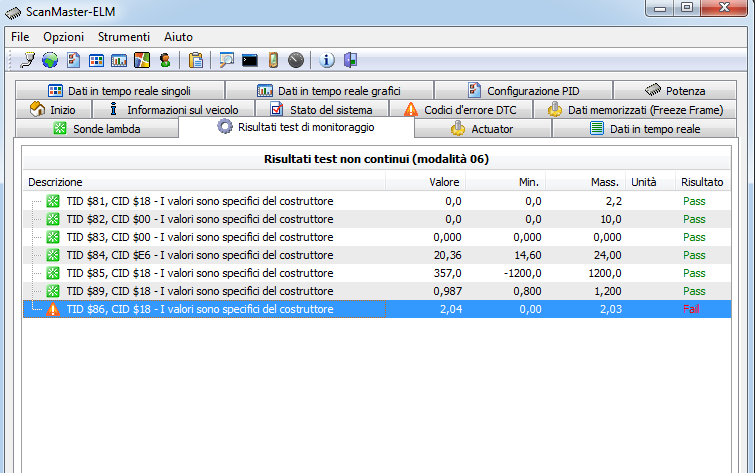

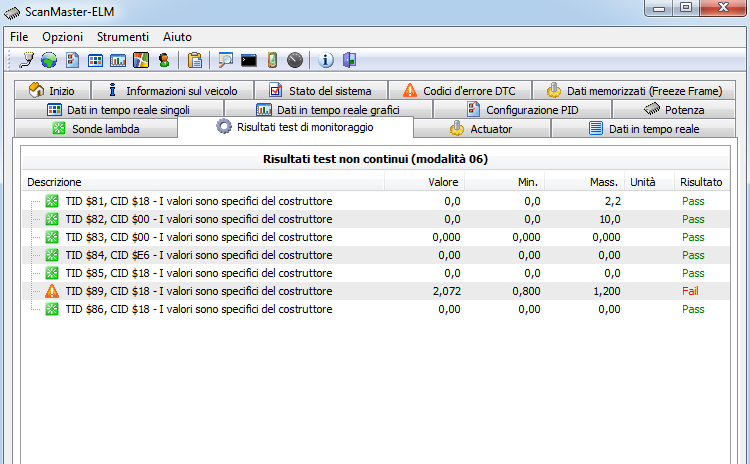

Io credo invece che sia il FAP intasato che quindi genera una pressione sullo scarico troppo elevata. Ma è solo una mia idea in realtà... perchè con la diagnostica non posso leggere la pressione e confrontarla con quella dopo il fap.

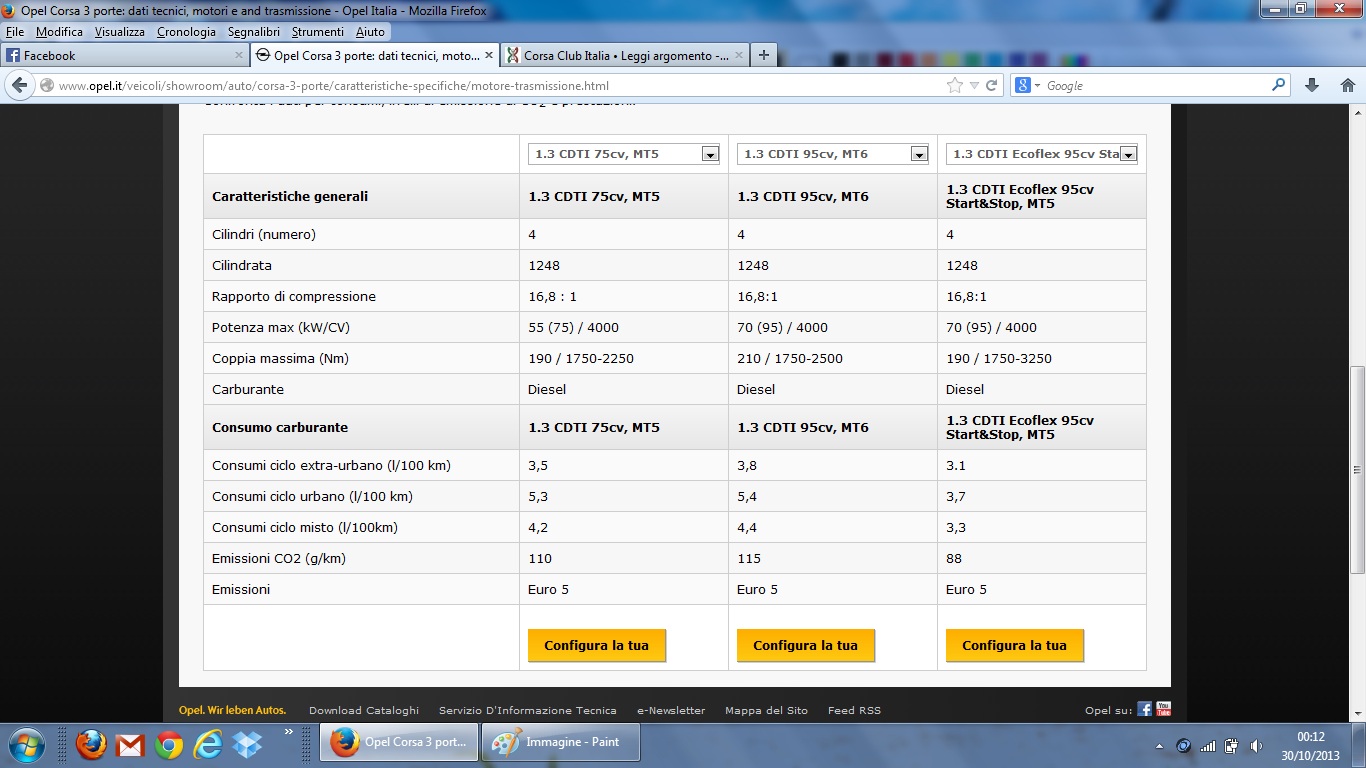

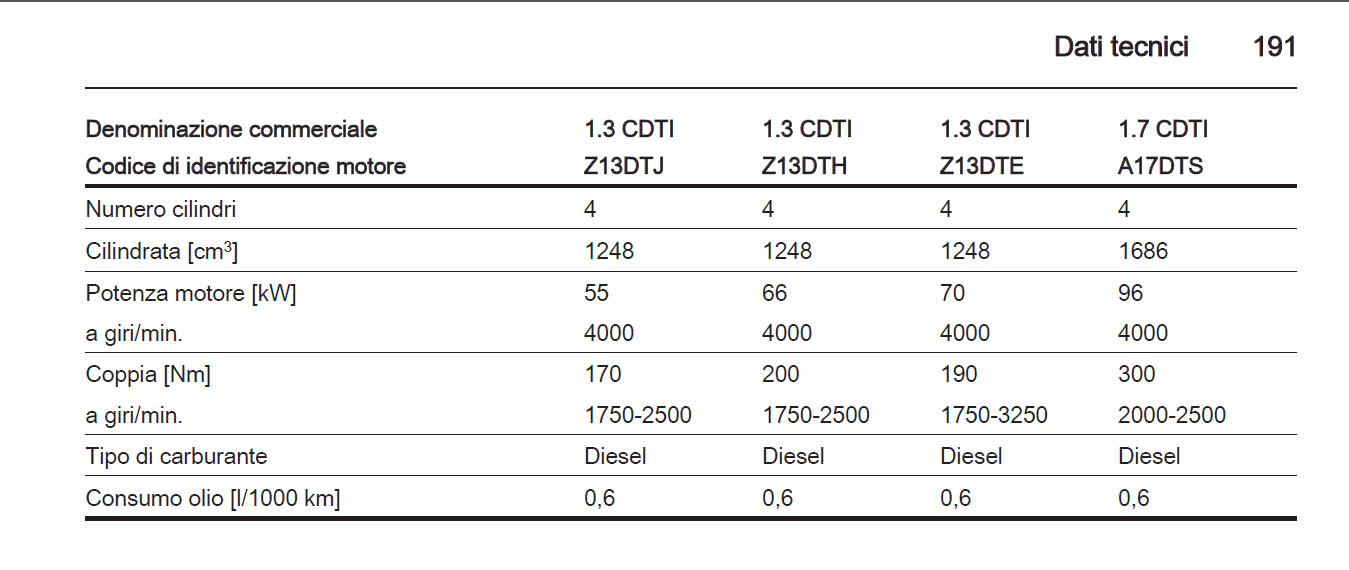

la mia in realtà non fa parte di nessuno di quei modelli che elenchi.

Z13DTE 95cv FAP Euro4 5marce ecoflex

A proposito domanda: il serbatoio è da 40 litri, ma qualcuno sa di quanto è la riserva? sul manuale non c'è scritto...

-- 30/10/2013, 9:21 --

ho trovato queste informazioni, relative però a una Astra J:

DTC Descriptor

DTC P2453 00: Diesel Particulate Filter (DPF) Differential Pressure Sensor Performance

--

Circuit/System Description

The exhaust differential pressure sensor measures the pressure difference across the inlet and outlet of the diesel particulate filter. The pressure difference across the diesel particulate filter increases as captured particulates in the diesel particulate filter increases. A diaphragm within the exhaust differential pressure sensor is displaced by the pressures change that occur from particulate matter loading. The sensor translates this action into electrical resistance. The engine control module supplies a 5 V reference circuit and a ground on the low reference circuit. The exhaust differential pressure sensor provides a signal voltage to the engine control module, relative to the back pressure as a function of exhaust flow, diesel particulate filter temperature, and diesel particulate filter soot loading. The engine control module converts the signal voltage input to a pressure value.

Conditions for Running the DTC

• The engine has been running and then turned off for at least 60 s.

• DTC P2453 runs continuously when the engine is running.

and

• DTC P2453 runs once after the ignition has been turned OFF.

Conditions for Setting the DTC

• With the engine OFF the ECM detects that the differential pressure is greater than or less than the calibrated threshold for 0.5 s.

• With the engine running the ECM detects that the differential pressure is greater than or less than the calibrated threshold for 1 s.

Action Taken When the DTC Sets

DTCs P2453 is a Type A DTC.

Conditions for Clearing the DTC

DTCs P2453 is a Type A DTC.

Diagnostic Aids

• A skewed or stuck exhaust differential pressure sensor will cause this DTC to set.

• The flexible part of the exhaust differential pressure lines are made of a high temperature hose that is protected by a braided covering. If the hoses are twisted or bent, they will not return to their normal size and shape. If the hoses are restricted, it may cause this DTC to set.

If any of the DTCs are set, refer to Control Module References .

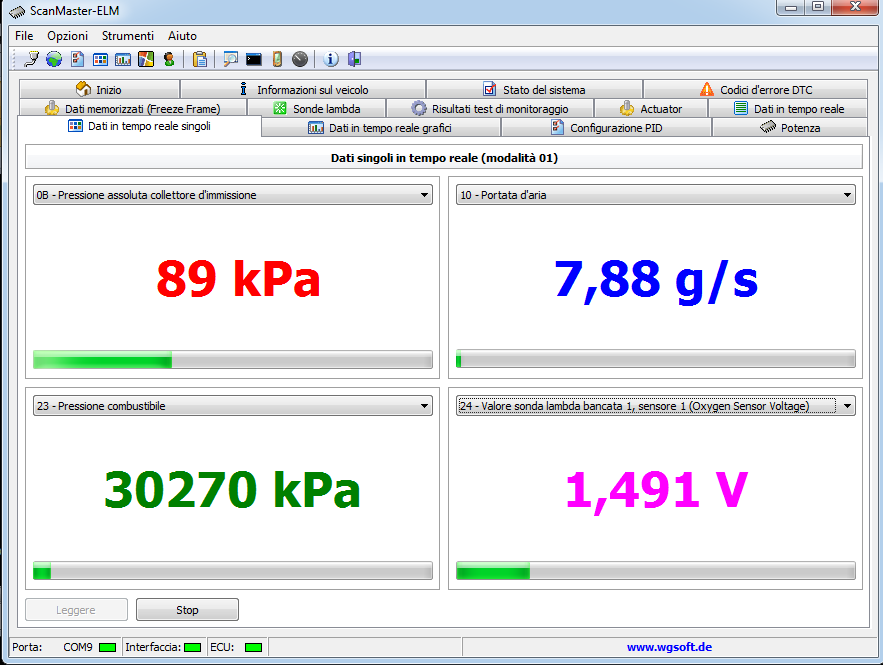

Ignition ON, engine OFF, observe the scan tool DPF Differential Pressure parameter. The value should be between -1.0 to +0.5 kPa (-0.14 to +0.07 PSI).

Engine running at a warm stabilized idle, observe the scan tool DPF Differential Pressure parameter. The reading should be between 0.0-3.0 kPa (0.0-0.43 PSI)

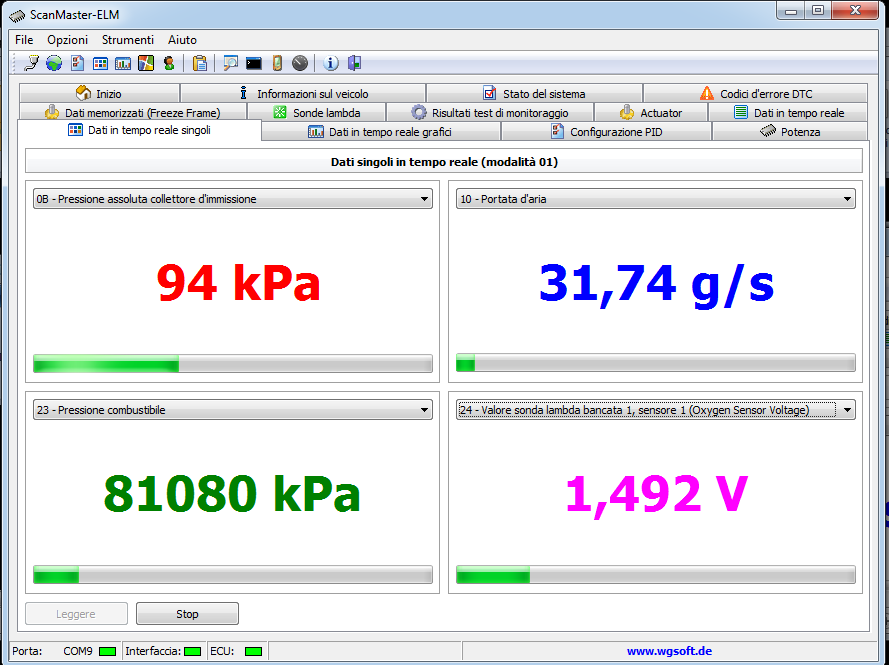

Engine running at a warm stabilized idle, observe the scan tool DPF Differential Pressure parameter. Increase the engine speed to 3 000 RPM. The value should increase.

Operate the vehicle within the Conditions for Running the DTC. You may also operate the vehicle within the conditions that you observed from the Freeze Frame/Failure Records data.

Circuit/System Testing

Note: Perform the Repair Verification after completing the Circuit/System Testing.

Verify the integrity of the DPF system by visually and physically inspecting any of the following conditions:

• Any damaged exhaust system components

• Loose or improperly installed exhaust system components

• Ensure the smaller diameter pressure line is connected to the front of the DPF and to the smaller port of the differential pressure sensor.

• Restrictions in the exhaust differential pressure sensor ports

• Damaged, bent, restricted, or kinked exhaust differential pressure lines. The lines should not be changed and should have a continuous downward gradient from the sensor.

Remove and inspect the flexible part of the exhaust differential pressure lines for internal restrictions.

If a condition is found replace the exhaust pressure lines.

Engine running, verify that the scan tool DPF Differential Pressure parameter is greater than 0 kPa (0 PSI), and increases as engine speed is increased.

If less than the specified range, and the parameter decreases as engine speed is increased, inspect for incorrect differential pressure line routing.

Ignition OFF, disconnect the harness connector at the B154 Diesel Particulate Filter Pressure Sensor.

Ignition OFF and scan tool disconnected for 90 s, test for less than 5 Ω between the low reference circuit terminal 2 X1 and ground.

If greater than the specified range, test the low reference circuit for an open/high resistance. If the circuit tests normal, replace the K20 Engine Control Module.

Ignition ON, test for 4.8-5.2 V between the 5 V reference circuit terminal 1 X1 and ground.

If less than the specified range, test the 5 V reference circuit for a short to ground or an open/high resistance. If the circuit tests normal, replace the K20 Engine Control Module.

If greater than the specified range, test the 5 V reference circuit for a short to voltage. If the circuit tests normal, replace the K20 Engine Control Module.

Verify the scan tool DPF Differential Pressure parameter is between 4.8-5.2 V.

If less than the specified range, test the signal circuit for a short to ground. If the circuit tests normal, replace the K20 Engine Control Module.

Install a jumper wire between the low reference circuit terminal 2 X1 and signal circuit terminal 3 X1. Verify the scan tool DPF Differential Pressure parameter is less than 0.5 V.

If greater than the specified range, test the signal circuit for a short to voltage or an open/high resistance. If the circuit tests normal, replace the K20 Engine Control Module.

Ignition OFF for 90 s, disconnect the X1 harness connector at the K20 Engine Control Module.

Test for less than 5 Ω between the 5 V reference circuit B154 Diesel Particulate Filter Pressure Sensor terminal 1 X1 and the K20 Engine Control Module 5 V reference circuit terminal 27 X2.

If greater than the specified range, test the 5 V reference circuit for an open/high resistance. If the circuit tests normal, replace the K20 Engine Control Module.

Test for less than 5 Ω between the signal circuit B154 Diesel Particulate Filter Pressure Sensor terminal 3 X1 and the K20 Engine Control Module signal circuit terminal 59 X2.

If greater than the specified range, test the signal circuit for an open/high resistance. If the circuit tests normal, replace the K20 Engine Control Module.

If all circuits DPF, and the differential pressure lines test normal, test or replace the B154 Diesel Particulate Filter Pressure Sensor.

Component Testing

Note: You must perform the Circuit/System Testing in order to verify the integrity of the exhaust pressure differential sensor circuits before proceeding with the Component Testing.

Static Test

Ignition OFF, remove the B154 Diesel Particulate Filter Pressure Sensor.

Install a 3 A fused jumper wire between the 5 V reference circuit terminal 1 and the corresponding terminal of the B154 Diesel Particulate Filter Pressure Sensor. Install a jumper wire between the low reference circuit terminal 2 of the B154 Diesel Particulate Filter Pressure Sensor and ground.

Connect a DMM between the signal circuit terminal 3 and ground.

Ignition ON, with the EN 23738-A Mityvac , slowly apply vacuum to the sensor while observing the voltage on the DMM. The voltage should vary and transition smoothly without any spikes or dropouts.

If the voltage is erratic, replace the B154 Diesel Particulate Filter Pressure Sensor.

Ultima modifica di

fabritrento il 30/10/2013, 8:21, modificato 1 volta in totale.

.gif)